![]()

Canada Bols courtesy Carlos

Simoes![]()

![]()

Distance from leading edge (inches)

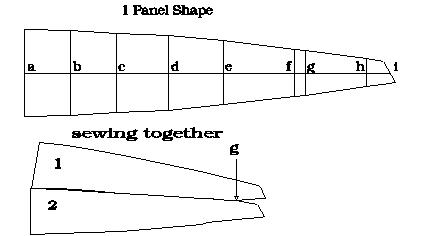

a = 0, b = 4.0, c = 8.0, d = 12.4, e = 17.2, f = 23.4, g = 24.3, h = 29.6, i = 31.6

Width of panel (inches)

a = 7.6, b = 7.4, c = 7.0, d = 6.5, e = 5.6, f = 4.2, g = 3.9, h = 2.5, i = 1.9

note: The angled end is 2.1 inches long and the longer edge is 1 inch

greater than the short edge. The point last point, 1.9 inches is on the centre

line like the rest of the points in the chart and is a vertical

height.

By Ed Hummel

ed.hummel@sympatico.ca

· Use & share these

plans & write me, Ed Hummel with your comments or questions. If you use

our plans to make a bol please send us a .jpg of your bols to add to our home

page.![]()