|

Download full-size plan

here

Build it light since there's very little stress

involved.

The Iris can be made without sewing by using 3M 9460 tape. It's not

cheap stuff, so maybe hand sewing or getting someone to sew the spar

tunnels to the sail would be easier than buying a 60 yard roll of tape.

BasicTools:

Xacto razor knife, scissors, a needle mounted in a cork or dowel holder,

lighter, metal ruler, pencil. An alligator clip is handy.

A sewing machine or needle and thread for sewing, OR some 3M 9460

double-sided tape for no-sew building. Gap-filling CA glue or superglue.

A piece of masonite or poster board to cut on.

Materials

Use Icarex or spinnaker cloth, something like on your stunt kites.

Heavy duty sewing thread for the bridle. I use cheap cotton/polyester.

Ripstop repair tape for nose, T, standoff and tail reinforcements.

Spars

0.050 inch carbon rod for the frame, with 0.030 inch for standoffs. These can all be

cut by rolling them under a razor knife on a cutting surface. Don't

press too hard or the cut will be ragged or split. Inch

to metric carbon rod chart

Fittings

Nine vinyl endcaps to fit the main spars, and one about 110 dia for the

center T.

A finger-long piece of insulation stripped from a piece of 18 or 16 AWG

electrical wire.

I use some from an old computer power supply.

Construction

Open the file in Windows Paint or similar program. Print the sail

template, paste it to stiff card stock and cut to shape with scissors.

The width should be 219mm from spine to wingtip. Use the template to

guide a sharp razor knife to cut the sail, either by folding the fabric

in half along the spine and cutting both layers at once or by cutting

one wing, then the other fom a single piece of fabric.

Cut two strips of fabric 12mm wide and a bit

longer than the leading edges folded in half to form the LE tunnels.

These are then positioned so the center crease is aligned with the sail

edge and either glued in place prior to sewing, or fastened with 3M

double sided tape. If using 3M tape, be sure to cut the tape into narrow

strips to allow room for the LE spar plus a little room for the LE

fitting notches. form the LE tunnels.

These are then positioned so the center crease is aligned with the sail

edge and either glued in place prior to sewing, or fastened with 3M

double sided tape. If using 3M tape, be sure to cut the tape into narrow

strips to allow room for the LE spar plus a little room for the LE

fitting notches.

Trim the nose and tails with scissors or knife.

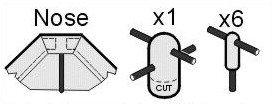

Cut a piece of fabric to form the nose

reinforcement and hand-sew or tape it in place as shown

Be sure to provide a nose pocket for the spine.

Reinforcements

Cut two 10mm square standoff reinforcements from ripstop tape and fold

them over the sail edge at the standoff points. Cut and install the

center 15mm square T patch and cut the hole through both the sail and

patch at the same time. I use a gasket punch, essentially a sharpened

steel tube tapped with a hammer on a wood block, to do this, but you an

fold along the spine line and cut with scissors. Now cut the half-round

notches in the LE to accept the LE fittings.

The sail is now ready to frame.

Prepare fittings s s

Pierce six small vinyl endcaps with a cork-handled needle heated with a

lighter. Make the holes smaller than the spars so they fit snugly.

Pierce holes in the larger vinyl cap to for the T fitting. The round end

will face the lower spreader. Now carefully make the holes for the

standoffs, taking care not to go bigger than the 030 rod.

Framing

Cut two LE spars slightly longer than needed. Insert the LE spars into

the place, installing the LE fittings at each notch, and install a vinyl

cap before sliding the spar firmly into the nose. Pull the tunnel snugly

to get the wrinkles out and secure the wingtip with a drop of CA glue.

Tension both wings equally. Install another vinyl cap to the spine and

fit it into the nose pocket, then slide the T-fitting in place so it

sits in the hole with the round end toward the spreader. Tension the

sail along the the spine and secure with a drop of CA glue at the tail

tip. A strip of 6mm 12mm ripstop tape on both side of the spine at the

tip reinforces it. Another small drop of CA will seep into the tail and

secure the edges of the tape. Trim the spine and LE spars flush with the

wing and tail tips.

The lower spreader now goes into place through the

T fitting and the remaining two pierced caps to hold the standoffs.

Cut two overlong 030 standoffs and four 5mm

lengths of the wiring insulation to form stops. On one end of each

standoff, glue the stop to allow the spar to protrude 3mm. Put each

standoff into place on the sail, with the stop against the sail, and

check for the proper length. On small kites, variations in construction

make it hard to give an exact length, so they must be made to fit the

kite. When they are trimmed to length, add the two remaining bits of

insulation to the other end of the standoff to keep the end from passing

the spar inside the vinyl cap and piercing it. Glue the standoffs to the

sail with a droplet of glue. Cut and install the upper spreader.

Bridling

Just match the leg lengths on the plan, with slipknots on the LE and

center tee, larkshead adjustment knots. Use a needle to install a

trickline from wingtip to tail to wingtip.

Flying

Tie the flying lines to the pigtails, equalize the lengths and tie the

ends to the flying bar. I use slipknots and slide them farther apart in

light wind, closer in higher wind. Wind the line on the bar through the

knocks and secure to the spreader with twist ties. This prevents

fumbling and tangling the thin line.

|