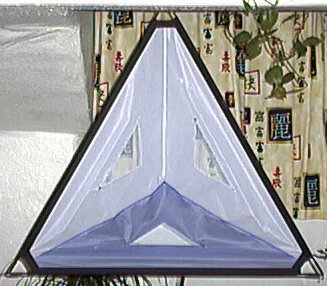

Team Triangle Vented

Designed by Wack made by Dave.

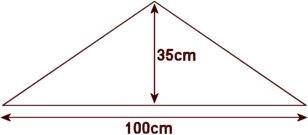

The Team triangle Vented is made in exactly the same way as the Standard. Firstly three sail sections are cut to the following dimensions:

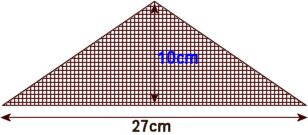

Now you have to cut out your mesh and stitch it onto the sail sections. The vents are made from a standard kite mesh usually used on large foils. Any kite shop in the UK can get this from one of their main distributers, or alternatively it is availiable from caravanning stores and is used for repairing mesh screened doors. The vents should be cut to the following dimensions:

The vents should be positioned in the centre of the three sail triangles:

The vents were stitched onto the front face using a zig zag stitch. The material behind the vent was then carefully cut away. Following this the main sections were sewn together, and the kite was constructed as for the Standard:

.............it is best to sew the sections together starting from the centre and moving towards the edges of the kite. We used the following standard sail stitch:

![]()

The red dashed lines indicate where the stitches were made. First two pieces are stitched together, then the left over seam allowance is stitch down. I always prefer to make the overlap on the darkest colour used. You Should know have something like this:

When the three pieces have been stitched together you will need to cut of the corners. The following image shows to make the cut so that the new edge will have a length of 9cm:

You should now be left with something looking like this:

The final task is to stitch on some protective dacron. We used 5cm wide dacron tape. First fold the tape over and score the edge to make it nice and sharp. All dacron pieces were cut using a soldering iron to seal the tape and prevent fraying. Firdt of all cover the 9cm cut edges, followed by the main sides of the kite. The sides should be stitched so that the dacron overlaps as shown here:

Finally the rods need to be added. We used 100cm lengths of 5mm excel tube on the standard version. The rods were joined using clear semi-rigid pvc tubing availiable from most DIY stores for use in pond fountains. A small amount of line was tied on at the very corners where the flying line was attatched. Wack and I had a difference of opinion on the knot to use! The two favorites were the Pursik and the Double Lark's head! If it moves a lot durng further test flights the line will be stitched through the pvc tubing to keep it in place.

Well that's it then, by now you should have a rather nice kite! If you have any questions about construction then leave it in the messages section of the site, and it will be answered next time we look at that section!